Ductility is an important property in the world of lifting. Chains

and lifting components, for example, consist of an alloy that not only

makes the steel stronger but also gives it more ductility. Ductility is

an important factor in the design and manufacture of lifting and

hoisting materials. A higher degree of formability ensures greater

safety. But what exactly is ductility and why does it improve safety?

First of all, we will explain tensile strength before we move on to

ductility. Tensile strength is the maximum mechanical load of a

material. When the maximum tensile strength of a material - in this case

steel - is reached, it will start to contract and eventually break. The

stronger the material, the more load it can withstand.

For example, Grade 8 steel is made from a Cr-Ni-Mo alloy that is

hardened and stress relieved. The steel is stress relieved during

tempering, but the hardness is also reduced in a controlled manner to

increase formability and impact resistance. The risk of embrittlement

such as stress corrosion cracking and hydrogen embrittlement is thus

reduced. The term "Grade" indicates the nominal breaking load, expressed

in Newtons per mm², for this material type. For Grade 8, this is

800N/mm².

Of course, one does not want a chain to break into two parts immediately

after exceeding the maximum tensile strength. Ductility is the ability

of a metal to deform under tensile stress. For example, ductile metals

can easily be pulled into a wire under tension.

Ductile materials have high toughness. The opposite of ductile materials

are brittle materials. These are materials that immediately break when

they reach their maximum tensile strength. Brittle materials are

referred to as non-ductile materials.

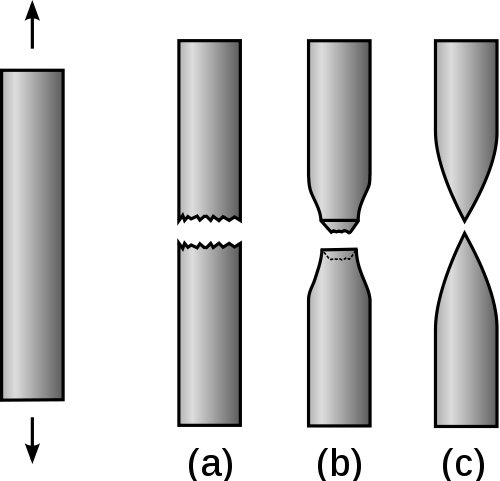

Pictured are materials that change from left to right from brittle to

tough, from non ductile to ductile. Chain (a) breaks without any

deformation. Chain (b) breaks with very little deformation. Both chains

are essentially low deformability. Chain (c) on the other hand has high

ductility and will deform before breaking.

The industry standard is that lifting components should have a minimum

formability of 20%. This percentage ensures that the deformation can

always be clearly seen and thus provides more safety.

A "safe" lifting chain or hook will therefore first show a visual

deformation before breaking. This ensures that timely action can be

taken before tragic accidents happen. It is also important that a visual

check is always carried out on lifting and hoisting equipment before it

is put into use. Lifting and hoisting equipment which has been

subjected to loads exceeding its maximum tensile strength will stretch

and deform due to its ductile properties. However, the deformation that

has occurred will not disappear when the tension is removed. Whenever

deformation is noticed, the material must be taken out of service

immediately.